3D printing to improve manufacturing productivity & lower costs

Digital & Technology

329 week ago — 4 min read

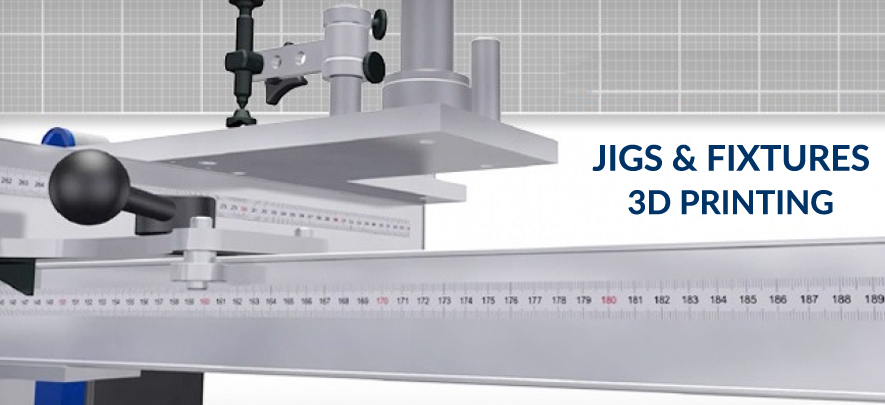

Summary: Manufacturing firms are constantly looking to increase productivity and lower costs. Lean manufacturing techniques such as the implementation of jigs and fixtures in a production line help achieve these goals. In simple terms, the jig is a tool that guides the cutting (or machining) tool. The most common type of jig is the drill jig, which guides the drill bit for creating holes at desired locations. The fixture is a tool which holds the work piece with the machine bed precisely at the desired location. The fixture also reduces non-productive loading, unloading, and fixing time of the work piece. 3D printing of jigs and fixtures can significantly lower manufacturing time and costs and improve production quality, writes Vishal Jariwala.

In manufacturing, to fulfil the high level of customisation and complexity of designs; to increase the speed and accuracy for the parts to be manufactured, the ideal solution is to produce jigs and fixtures. Additive manufacturing or 3D printing is a technology that reduces the production cost of jigs and fixtures up to several percent.

Previously, jigs and fixtures were designed and tooled for traditional production methods. Making a mould of the same was the method followed. By adopting new 3D printing technology, jigs and fixtures can be printed overnight, which eliminates the cost of moulds from the production equation. This directly impacts and reduces the production time, thereby accelerating product delivery. Designing for moulds, tooling, and production of moulds previously used to take days to weeks. But now, it can be 3D printed in one day or less, which gives the design engineer greater flexibility. This has led to rapid increase of jigs and fixtures within the entire production process. Cost and time are greatly reduced, and the devices are utilised in different places and applications which were not even considered previously. In other words, 3D printing lowers the threshold for justifying a new tool, which allows to address the unmet needs throughout the production process.

In manufacturing, production quality depends on the reduction of defects which is reflective of the application of jigs and fixtures. Poorly fabricated and assembled products are a direct result of poorly manufactured or lack of jigs and fixtures. Without assisted devices (jigs and fixtures) more end products are reworked; thus, increasing the cost of production and compromising quality.

Automotive industry seeing the highest level of 3D printed jigs & fixtures adoption

The automotive industry is currently seeing the highest level of 3D printed jigs and fixtures adoptions. Companies like Audi, BMW, Porsche, Volvo use them mostly to fit, connect, and hold components together at the production line. The BMW Group has gone a step ahead and introduced customised 3D printed assembly support tools for their employees. Designed for each individual, the flexible finger coats make certain actions easier to perform efficiently while keeping people’s thumbs safe.

3D printing of manufacturing aids like jigs and fixtures can dramatically save production time and costs and enhance quality of production.

To explore business opportunities, link with me by clicking on the 'Invite' button on my eBiz Card.

Disclaimer: The views and opinions expressed in this article are those of the author and do not necessarily reflect the views, official policy or position of GlobalLinker.

View Vishal 's profile

Other articles written by Vishal Jariwala

Importance of 3D printing in education

359 week ago

3D printing and its application

386 week ago

Most read this week

Comments

Share this content

Please login or Register to join the discussion