The supply chain & its impact on agricultural food waste in India

Agriculture

381 week ago — 14 min read

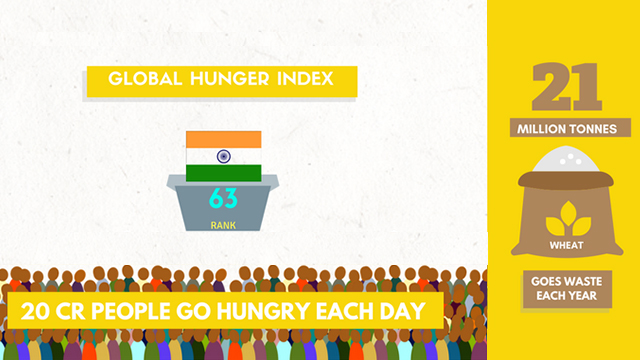

India is a country blessed with a lot of arable land. A vast majority of populace is still involved in agriculture. Yet, food wastage is common and it is a stark truth that a significant percentage of the population goes hungry everyday or survives on just one meal. India State Hunger Index estimates that 200 million go hungry everyday. That is almost one in six people. The problem, of course, is faced by other countries as well - but India's issue is acute.

Food wastage is growing to alarming proportions while not many administrations are necessarily paying proper attention to the issue at hand. As per the United Nations’ Food and Agriculture Organisation (FAO), close to 1.3 billion tonnes of food goes to waste every year. This wastage is costing the world economy a mind boggling $750 billion. Besides the large scale economic disaster, the food wastage is generating nearly 3.3 billion tonnes of greenhouse gas emissions. Rice being the staple food in most East Asian countries, such as China, India, and Japan to name a few are incredibly populated. The East Asian pockets are generating a lot of waste (mainly rice). Scientists have proven that decaying rice releases methane, a dangerous greenhouse gas which fuels global warming.

Food waste is not an isolated concern for the developing and underdeveloped nations; it is a serious cause for concern for the entire planet. In the United States alone, the National Resources Defence Council (NRDC) pegs 40 percent of food going completely uneaten.

Most other countries in the survey consume a majority of landmass to graze cattle and raise poultry, while India utilises most of its land for agriculture, leading to higher wastage of cereals, pulses, fruits, and vegetables.

How can India lose so much food you ask? Well, the matter is that we are grossly inadequate in cold storage facilities in the country. Based on a recent study conducted by IIM (Kolkata), the actual figure projects that India has the capacity to offer cold storage to only 10% of total food production. Immature supply chain management adds to the burden of food safety and has turned India into a major contributor of food wastage both at pre and post harvest phases (especially cereals, pulses, and vegetables).

The resources used to sow seeds and grow food also go to waste. 25 percent of water goes to waste which is used to produce food, while millions of Indians are deprived of access to fresh drinking water, leading to further health care crisis. The other burden farmers have to share is a brutal concoction of land degradation due to deforestation, reliance on unsustainable agricultural practices, and groundwater extraction.

The FAO initiative in India

The FAO (Food and Agriculture Organisation of the United Nations) carried out field studies to generate better understanding on food wastage across India in 2016.

The purpose of conducting this survey/investigation was to arrive at pointers which would form the bedrock to modernise the country’s supply chain as well as training producers on best practices.

Expanding storage and distribution centres across rural India and thereby raising general awareness about food production management and distribution on a large scale. This study conducted in India is a second of its kind driven by the SAVE FOOD initiative.

What is the cause of food loss

India has a unique problem of facing myriad issues at various stages of the food supply chain. While it is challenging to maintain highly perishable foods for longer, India is an exception in losing the highest ever spoils in the food grains (agri food) category. Especially wheat and rice.

In the immediate aftermath of gaining independence, India was deprived of a self sustaining agri food sector and was obviously dependent on imports until the mid 60s. At this stage, the citizens were also deprived of the luxury of quantity to even think of wasting food.

- Impact of Green Revolution: It took the green revolution to transform India from a food scarce nation to one with abundance. This immediately led to wheat rotting in warehouses with alarming regularity and started generating hundreds and thousands of tonnes of food wastage.

- Result of weak procurement norms: The other worrisome factor which leads to food wastage is the relaxed procurement norms designed to help farmers affected by intermittent rains. This means the quality of produce is low and thereby can’t be stored for longer, leading to wastage.

- Allocating for subsidised food will never be the antidote: Most state governments in India set up a sizeable portion of produce towards subsidised ration for the underprivileged and midday meals at schools and colleges. Even these initiatives leave tonnes of produce unsold in the open market.

Can packaging and supply chain initiatives solve the problem

Back in 2012, two researchers from the Massachusetts Institute of Technology (MIT) arrived in India to study the market conditions and its stakeholders with an aim of presenting possible solutions to reduce food wastage in the country. The two member team were here for five months with the hope of finding sustainable approaches to reducing agricultural food waste in India. Their report claims that nearly 20-40 percent of the food grown is spoilt before it reaches consumers.

The team knew very well that each country (developed or otherwise) has its fair share of challenges in dealing with food wastage. However, they found two unique factors indigenous to India in solving this problem.

1) Most data and analysis available about agricultural waste in India is anecdotal and

2) Various factors, including demographic and legislation, have limited the average farmer to work with just 2 to 4 acres of land and a whopping 70 percent of farmers in India work on land size of less than 1 hectare (2.5 acres). This means that typical farmers and supply chain stakeholders do not have the necessary means to make technology and infrastructure investments to drive production and distribution efficiencies (you can read the entire report here).

Packaging and storage

Improper packing and storage leads to severe losses in terms of value and weight. Jute bags used to pack and store grains do nothing to keep moisture or pests away, thereby creating a need for a low cost storage bag which helps to ward off external moisture and pests and rodents alike. The grains develop enough moisture to prevent itself from rotting. External moisture (such as rain) coming in contact with the grains will imbalance the quality of the grain itself. This would go a long way to reduce loss during transportation for a variety of crops.

India has two types of agri production units:

- Mega production states such as Punjab, Haryana, and Andhra Pradesh with plans to build modern silo storage facilities and,

- Small rural areas isolated individually, but put together would amount to significant production numbers that lack modern storage facilities.

This creates a dire need to build multi-purpose, low-cost storage facilities using locally available raw materials. The idea is to build these facilities which can keep the produce from damaging elements and pests, and allow for better temperature control.

- Storage solutions: If we closely analyse the journey of food grains from farmers to mandis, then onto retailers from where the products reach the common man, undesirable storage practices have led to a loss of grains. Though we all can admit that winding the loss of grains to zero is nearly impractical, but improving our storage practices can yield in massive savings. Especially considering the number of people who don’t have access to food on a daily basis in the country.

- Food storage options While transporting: Each grain of crop releases enough moisture from within to keep the nutrition intact. Jute bags are notoriously moisture friendly and absorb a lot (rain). Storing grains in jute bags while transporting in open trucks exposes the crops to different elements. This means the crops will age sooner and go to waste quicker. To avoid this, one can use Pallets and Crates to store grains (even fruits and vegetables). There are two varieties available- one which is compact and airtight to keep moisture away, and two, with vents for vegetables and fruits.

- Storage options at godowns: Once the grains are transported and moved into godowns, one can use high-grade plastic drums as local storage options. This way the materials stay intact and safe. Storage drums do not take up too much space, as a result, they help in utilising every square foot of space in the godown. Another material handling product is the Platform Trolley. They are immensely helpful in moving heavy loads of materials with ease. Grains such as Rice, Wheat, Pulses are not as vulnerable as fruits and vegetables to the elements and rough handling during transportation. Products such as Sugarcane (which is a major producer of), and other fruits and vegetables need to be put in cold storage. Here, the ideal storage option is the ice box crates which are compact and keep the materials intact.

- Storage and package options for retail: Before moving the products from the distribution centre, products are bifurcated into small packages in different sizes. Usage of Ziplock pouches is considered to be an expensive option (but the truth is far from it). High-grade Ziplock pouches (transparent or otherwise) keep the nutritional value of the food product intact and can weather rough handling during transportation.

- Policy recommendations: There is a scope and need for state and central governments to make major policy changes such as redefining the role of FCI and incentivising and motivating the private sector to invest in all facets of agri production and distribution will go a long way as steps towards solving major issues among which food wastage, a devil looking straight into our eyes.

Innovation has begun within the country

As sports fanatics, like most Indians, we see an analogy of how the Indian athletics system is woefully administered and yet we are able to produce remarkable talent from remote corners of the country. We can draw parallels from the aforementioned scenario to the R&D and innovations sprinkling from the knowledge rich diaspora from colleges and universities alike.

There are these three students who have conjured a simple and a fantastically innovative tech that uses solar power to dry food. Drying food enables farmers to preserve and retain the nutritional value of food produced at less cost, thereby reducing food spoilage and turning profits for farmers. Collaborative work like this has started a minor revolution among young Indians to create Indian solutions to Indian problems, especially in the agriculture sector where a majority of India is dependent upon for employment.

Their creation simply called the Solar Conduction Dryer (SCD), has won recognition from Dell. And the trio received US$60,000 in prize money to help fund and commercialise their project.

International Venture Capital Funds show keen interest in startups aiming to fix supply chain Issues

Most Venture Capital and Angel funds get into the pockets of fancy internet enabled businesses such as e-commerce, retail, financial tech etc. However, Unitus Seed Fund was first to realise the potential of businesses offering cutting edge solutions for the agricultural sector in managing and distributing food produce. Will Poole, the managing partner, says it’s an emerging area, which can unleash umpteen opportunities for startups and strengthen the supply chain in India agriculture. Unitus has funded a startup in Chennai, after a rigorous selection process of over 100 pitches.

How other countries are tackling food wastage crisis

One way India (public and private sectors) can seek live examples of simple and cutting edge solutions to solve the food wastage crisis is by looking at how developed countries are finding innovative solutions to tackle similar problems.

For instance, France has passed a law making it mandatory for supermarkets to give away unsold food items to charity or hand them back to farmers who can turn them into fertilisers.

Meanwhile, on the other side of the Atlantic, Canada has achieved a remarkable feat of delivering food ingredients to cook over 22,000 meals every day. The country’s administration has taken a cue from France and recovers unused food items from manufacturers, retailers, restaurants, and other stakeholders. These initiatives, while not being revolutionary solutions, have begun to cause major disruption in tackling food wastage.

To explore business opportunities, link with me by clicking on the 'Invite' button on my eBiz Card.

Article source: https://bizongo.com/blog/how-supply-chain-influences-agricultural-food-waste-in-india/

Disclaimer: The views and opinions expressed in this article are those of the author and do not necessarily reflect the views, official policy or position of GlobalLinker.

Network with SMEs mentioned in this article

View Shalmali 's profile

SME Inspirations

Other articles written by Shalmali Patkar

13 unusual materials used in eco-friendly packaging

367 week ago

GST Fundamental: Maintaining accurate records

377 week ago

Most read this week

Comments (1)

Please login or Register to join the discussion